Machinery

Our product portfolio

High performance processing equipment

Based on the long experience as a starting point, careful looking at the future, combined with the study and design of new technologies to improve production processes in animal feed: this is the mix that makes LA MECCANICA a pioneer in the field of plants for feed mills. The production program covers each single machine which composes a plant of pellet production. Tools built and calibrated according to the needs of the customer, allow a continuous monitoring of the production cycle and make it the most efficient by every single step, with constant updating of computerized systems which control the plant processing. Click on the photo of the plants : you can understand the quality level of LA MECCANICA and find the specifications of each machine.

Pellet mill

La Meccanica builts 14 different modells of pellet mills with power ranging from 10Hp to 500Hp that are used in the production of animal feed, wood & biomass, fertilizers.

VIEW MORE

Crumbler

Heavy duty constructions

The cutting rollers are adjustable and spring-mounted to protect against damage which could be caused by foreign objects

Rolls: rolls diameter 220 mm

Rolls length: 1200 - 1800 mm

Hammer mills

Our hammer mills for the Animal Feed industry, cover power ranging from 100 to 350Hp and for Biomass from 100 to 750Hp.

The capacity depends on the type of raw material, formula and required grinding structure.

Ribbon mixer

Mixing performed via two mixing ribbons mounted on a common shaft working in apposing directions.

Horizontal, single shaft, twin ribbon mixer

Shaft: on heavy duty self aligning roller bearings

Double ribbon type: on central axe with counterflow mixing action

Paddles mixer

Our mixer meet the following specifications:

Accuracy is guaranteed mixtures homogeneous with a variation coefficient of <5%

The homogeneity is achieved after a short a time (2-3 min)

The mixed material is carefully treated.

Coolers

These are specialty cooling machines developed for cooling and drying high temperature pellets after pelletizing.

We use 3 types of coolers: horizontal, vertical and counterflow.

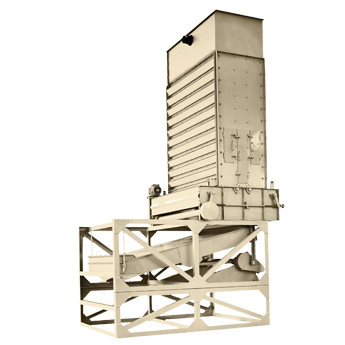

Vertical cooling group

Inlet hopper made in stainless steel, complete with two product sensors: rotating

VIEW MORE

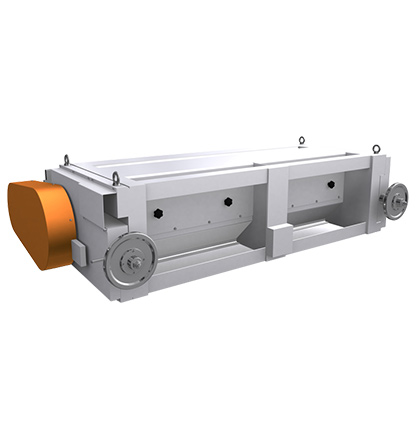

Horizontal cooler

Cooling deck composed of trays made in stainless steel AISI 430 fixed on both side to high specification chains

VIEW MORE

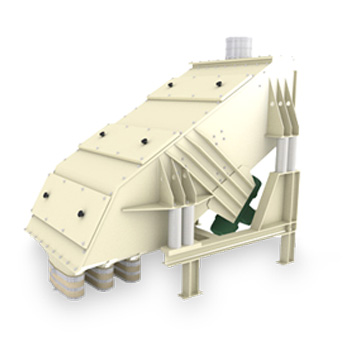

Sifters

The product in the inlet of the sieve comes leveled on all the width material is evenly distributed across the screens by means of a static distributor adjustable from the exterior

The robust casing is constructed in 3 mm mild steel with lateral reinforcement

It is mounted on 8 “soft” springs ensuring all dynamic vibration is transferred to the sieving action

Rotative screener

The Rotative Screener consists of a grid of sieving rotating inside a cylindrical chamber

VIEW MORE

STHT Processor

Expander is a machine similar to an extruder, combining temperature and pressure to treat and condition raw materials to provide a crumb with improved nutritional value to that of conventional feeds.

VIEW MORE

Sanitizer

The variable-pitch feeder is driven by a continuous variable speed hydraulic gear motor.

It is equipped with an overflow and emptying safety device.

The whole body of the screw feeder in contact with the feed is made in stainless steel, including the shafts.

The feeder is electrically heated from the outside. The outer surface is lined with insulation to keep the temperature constant.

Vacuum fat addition

The vacuum mixer was conceived to integrate liquid ingredients (i.e., oil and melt fat) directrly in the extruded product as soon as it has gone through the drying process.

The liquid absorption is guaranteed on a product with diameter ranging from 2 to 18 mm. with maximum humidity up to 8%.

The percentages of liquid ingredients that can be added to the product range from 8 to 20% and the top amount of achievable vacuum is -20mBar.

Continuos cold fat addition

The fat addition machine enriches the feeds that need a high percentage of fat, such as poultry feed, without injuring the compactness of the final product. The cycle begins after the sieving of the pellet that makes it homogeneous, well filled and dry with a fat percentage ranging from 7 to 11%.

VIEW MORE

Molasses Addition

Machine completely made in stainless steel.

Large hinged door for inspection to clean easily the machine.

Protections and security systems to CE standards.

Non-stick internal coating made in plastic plymer easily changeable.